With comprehensive multi-discipline design and project management expertise, BEINIT Energy’s teams of highly skilled professionals provide innovative solutions to a variety of clients through 2 interconnected streams of delivery.

BEINIT Energy’s in-house specialist engineering capability encompasses geotechnical, technical safety, environmental, seismic and marine. Our project management and teams are led by discipline-specific experts. We continually strive to develop smart solutions that enhance delivery efficiency and optimize constructability to add value to our client’s bottom line.

Technical Excellence stands as the foundation of our promise to apply the very highest standards in design, project management and stakeholder collaboration to realise the successful delivery of our projects.

At BEINIT Energy we understand that design and project management are vehicles to create real and lasting value for our clients. With that objective, we focus on understanding what value creation means to our clients and align our efforts accordingly to maximise impact of that goal.

While such primary drivers of safety, cost, quality and schedule remain key to our delivery, we look beyond these to understand the benefits our clients are seeking when undertaking large and complex projects; our priority then becomes a matter of reinforcing our commitment to ensuring our client’s vision is realised.

As a result of being an independent small company in a big industry, BEINIT Energy maintains great agility and responsiveness to our clients. This commitment is led by our executive team who remain unwaveringly hands on in all they do to support out clients in achieving their desired results.

We are committed to providing a quality service to all our clients and we work continuously to improve our delivery through in-house professional development, client interaction, teamwork and work process improvement.

The organisational culture in BEINIT Energy revolves around achievement and enjoyment. We employ talented and skilled individuals and we provide a motivating and rewarded environment in which they can excel. Our people are always encouraged to reach their maximum potential and to express their abilities through their projects.

We are learning-based organisation and we achieve this through knowledge sharing, mentoring, and continuous professional development. We believe in the premise that everyone should really enjoy their work and this work must fit within a greater life experience. We are therefore committed to ensuring our staff achieve this important work-life balance and we invest significant time and resources to this end. Investing in Our People form the third and final pillar of the BEINIT Energy promise and is testimony to our philosophy that everyone has a positive and enriching experience during their tenure with BEINIT Energy.

CONSULT

CONSTRUCT

Projects

BEINIT Energy were commissioned by aggreko Middle East for end user CC Energy Development Oman to Design, Engineer, Manufacture, Procure, Supply, Construct, and Commission a Fuel Gas Conditioning Package (FGC). The project was completed on a fast-track basis and took just 4 months, from start to finish. The primary scope is a cooling system capable of reducing the temperature of the 1.2MMSCFD of sweet gas from 70DegC to below 40DegC and uses a two stage condensate filter to remove all liquid hydrocarbons with the gas at a pressure between 0.8 and 2.5 barg.

Projects

BEINIT Energy recently refurbished a Single Point Mooring Buoy for Belemaoil Producing Ltd and their partners Nigerian National Petroleum Corporations (NNPC) for OML-55 field export line. BEINIT Energy provided a single-source turnkey design, construction and installation of marine terminals for the complete range of import/export applications. Delivery was reduced from 18-24 months by utilising an existing buoy that was previously deployed by Shell in the Gulf of Oman.

Projects

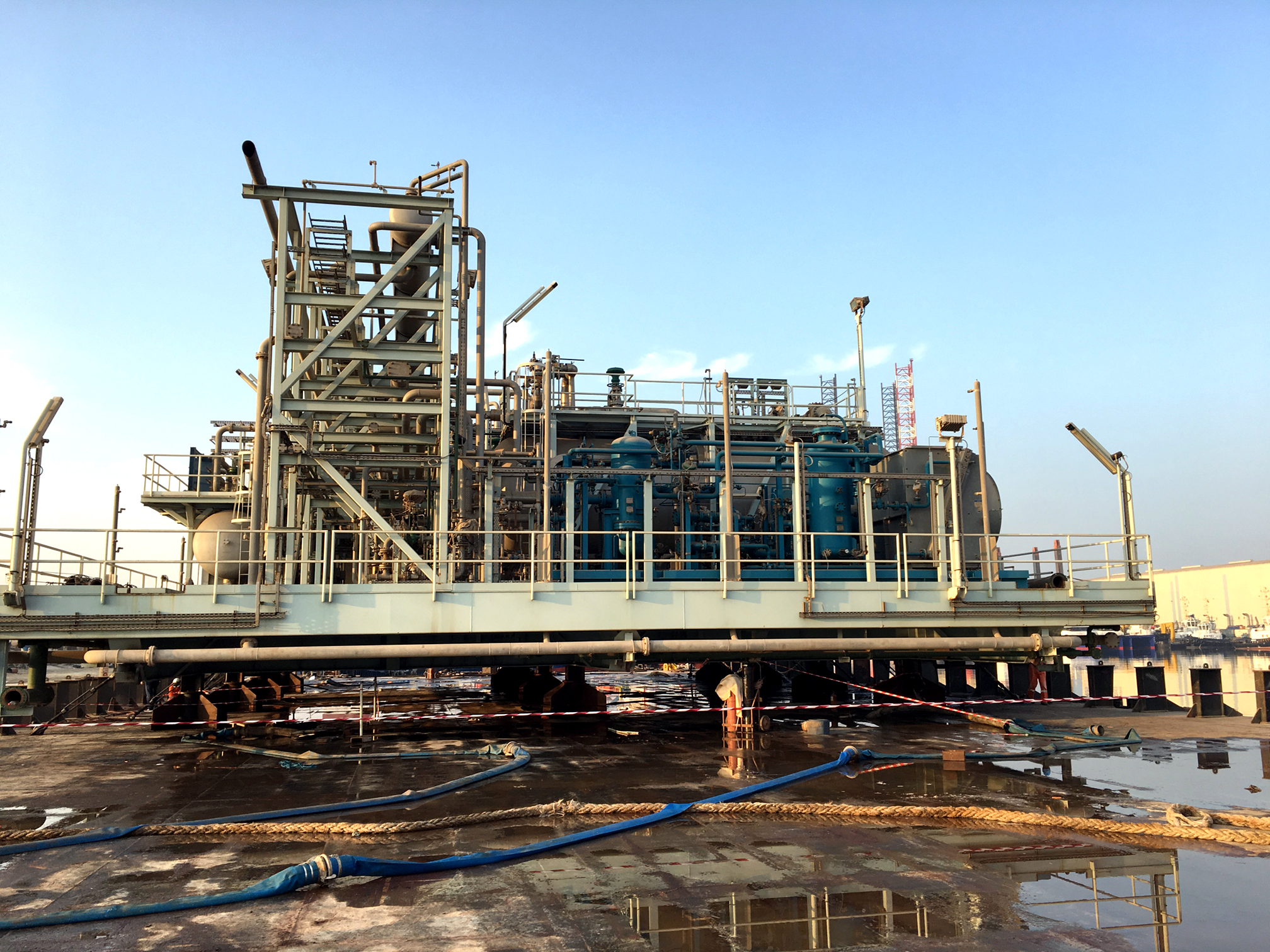

BEINIT Energy specialises in fast-track projects using certified in-stock crude and gas production assets. One example is the module M20 currently in-stock in the UAE. This process plant is capable of producing 55,000 bbls/day of crude oil, 13,750 bbls/day of water and 40 mmscf/day of gas.